The word gabion “comes from an old italian word, gabbione, that means „big cage “. Around 7000 years ago, early gabion type structures protected the bank of river Nile. In Middle Ages, gabions were used as military forts. In earlier history, civil engineers have extensively used gabions for stabilization of banks, coasts, highways and erosion control of slopes. From the banks of river Nile, where they were created up to today, gabion walls are a benefit for the landscape. It is used for thousands of years as a gravity type retaining structure and makes a attractive, efficient and cheap wall system.

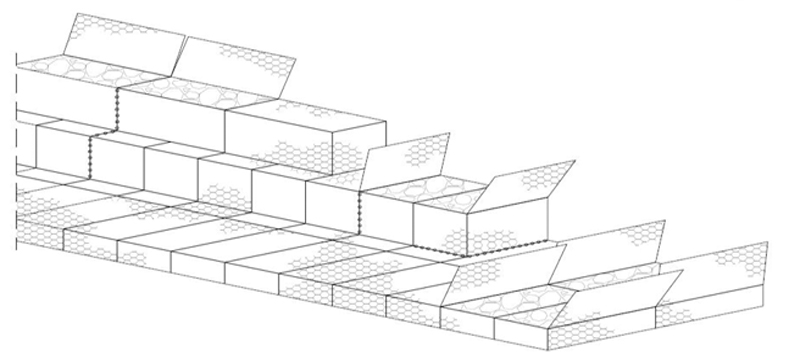

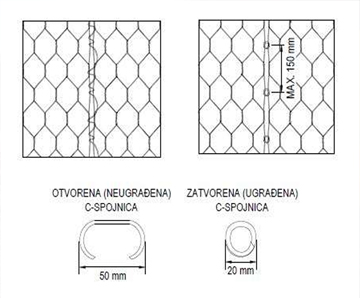

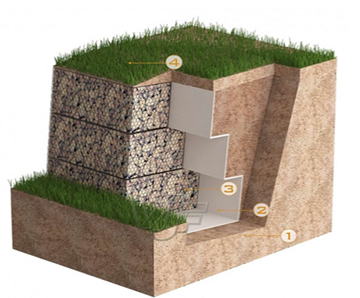

Gabion walls are executed mainly in the purpose of soil stabilization behind the wall, but it can also be executed as a cover wall. The wall is made from gabion baskets that are stacked in one or more rows, depending on the height of the wall. Baskets have a cage shape and are closed on all sides. They are made from a galvanized hexagonal meshes and Brocken rock that are placed in the baskets. Retaining structures are formed by stacking gabion baskets in a proper schedule and present an alternative solution for concrete structures in the area of soil stabilization.

Gabion walls have an application mostly in road engineering, e.g. construction of roads, embankments, retaining walls, slope protection, water barriers etc., and can have different functions:

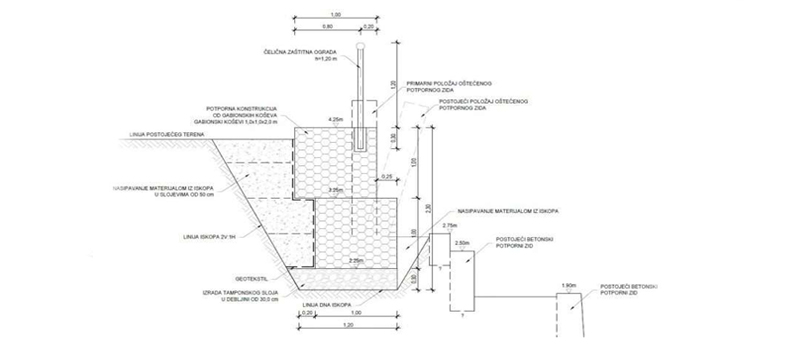

First row of gabion baskets is placed on a foundation made from stone material or concrete, depending on project requirements. The second row is placed on a way that it is moved from the outer edge toward the back in a certain distance. After completing the basket, the space behind the basket is filled with a suitable material up to the height of the upper gabion row.