The Reinforced soil technique is a thousand of years old concept, and has experienced different types of reinforcing material, from bamboo to steel strips, from tree branches to geogrids. The synthetic types of reinforcement have the advantages of providing greater durability, strength, proven experience and finally a more theoretical design approach.

Reinforced soil walls comprise of some type of reinforcing element incorporated into the fill soil in horizontal layers to help resist lateral earth pressure and to assure stability of the structure. These systems are more flexible and faster to construct than other available conventional systems of retaining soil.

The major advantage of using Geostrips for designing and building a reinforced soil wall is that the construction is quite simple and rapid, experienced craftsmanship is not required and the final overall structure is flexible and ductile allowing differential settlement of the base without failure.

A variety of facings can be used and the resulting aesthetic options can be provided. The most popular facing currently used for RS wall construction worldwide is with Modular Concrete Block Units and Pre- cast Concrete fascia Panels. These are popular because of their aesthetic appeal, ease in installation, higher durability and flexibility.

For static and seismic analysis, the following documents were used:

“Mechanically Stabilized Earth Walls and Reinforced Soil Slopes – Design

and Construction Guidelines”,

FHWA NHI-10-024 and FHWA-NHI-10-025,

2009.

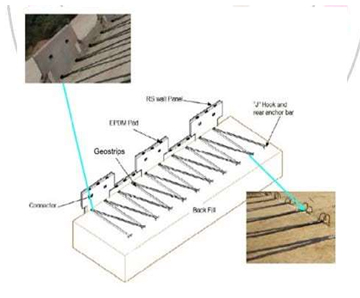

Reinforced soil wall comprises of pre-cast reinforced concrete fascia panels, polymeric strips, Geostrips connected to the pre-cast units by passing around cavity shaped Connectors and passing around anchor bars at the rear, the earth fill and accessories, as shown below-

The Connectors are cast into the panels. Geostrips is generally laid in zigzag pattern passing around the rear anchor bars. Rear anchor bar is used just to keep the Geostrips in position during the filling and compaction operation and has no design significance. The Geostrips strips are generally spaced at 1.0 m c/c in horizontal plane and 0.8m c/c in vertical plane.

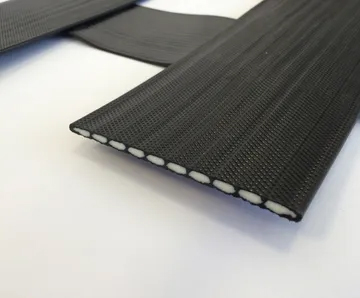

Geostrips comprise of tendons made from high tenacity polyester yarns concentrated in ten separated bundles and encased in a durable polyethylene sheath. The polyester yarns are placed in tension and polyethylene is then co- extruded on to the polyester to form polymeric strip. While polyester is the load bearing element, polyethylene sheath protects the polyester yarns and provides the size and shape to the strips.

Geostrips are supplied in various strengths between 30 to 100kN. The width of Geostrips varies between 85 to 90mm depending on the strength of strip.

The Connector is made up of High-Density Polyethylene (HDPE) and comprises of a cavity which is provided with a sleeve near the bottom through which the Geostrip is passed. A lid is provided over a connector to restrict the flow of concrete slurry side. The Connectors are cast into the panel and are used to connect the Geostrip to the panels through sleeves.

For Geostrips up to 75kN strength, 100mm deep Light-Connectors are used while for Geostrip with more than 75kN strength, 145 mm deep Connectors also known as Heavy- Connectors are used.

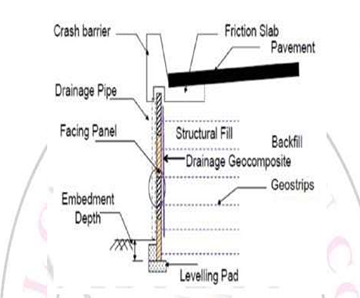

Drainage composite is a specifically designed geo-composite to meet the drainage and protection requirements in structurally demanding water draining applications. Drainage composites effectively eliminate hydrostatic pressure against below- grade structures and aid in dewatering saturated soil by collecting and conveying groundwater to a drain pipe for discharge.

Drainage geo-composite which are made of lightweight three- dimensional, high- compressive strength polyethylene core and heat bonded polypropylene geotextile, provided on one side or both sides as per requirements. The drainage composite may also be provided with geomembrane on one side to act as hydraulic barrier and at the same time drain of excess water for area above the drainage composite.